Replacement Screens for Swaco Mongoose/Meerkat Shale Shakers

DESCRIPTION

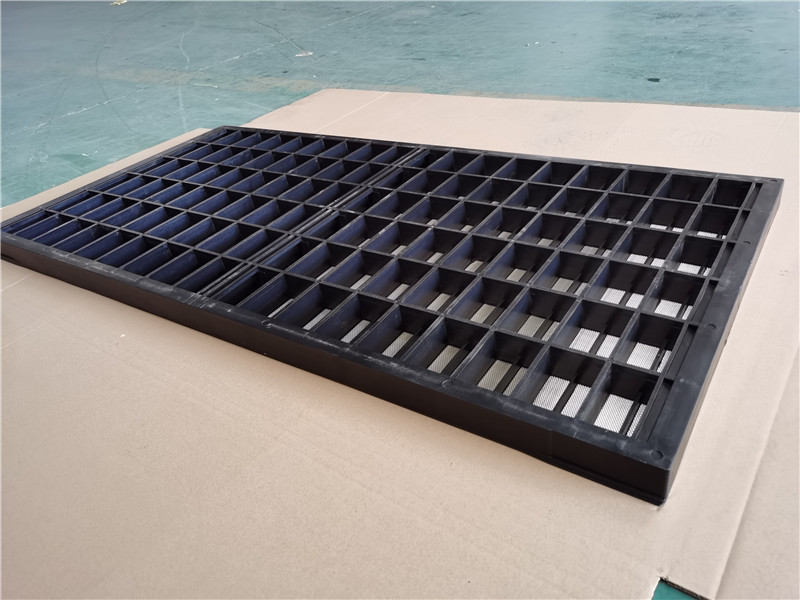

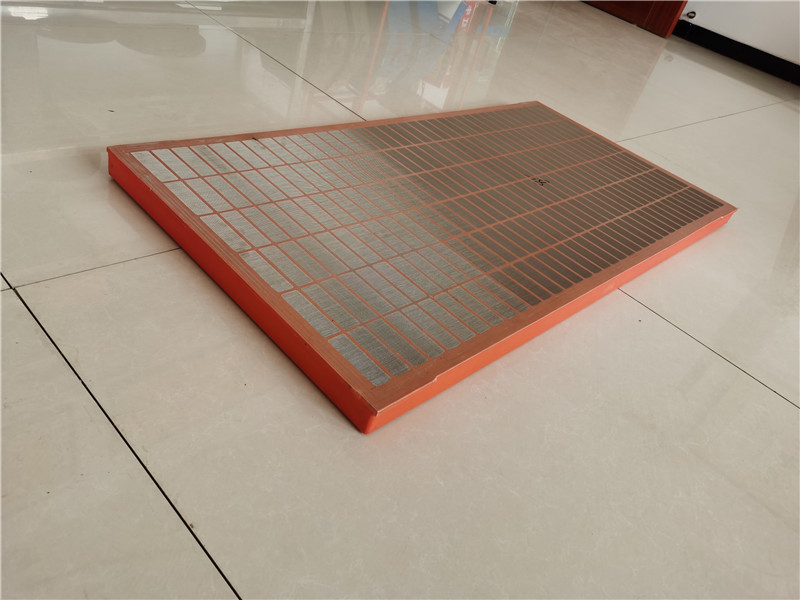

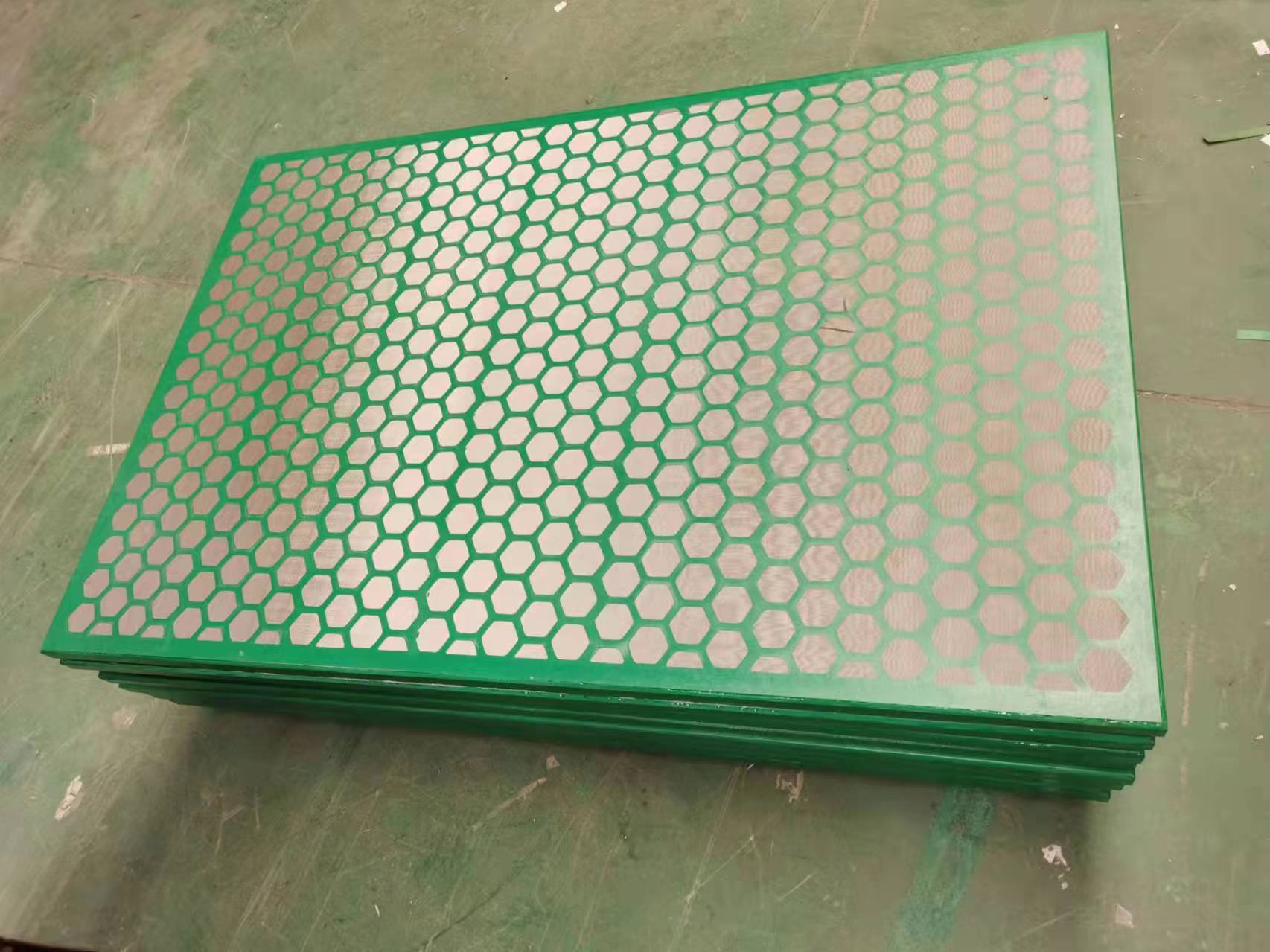

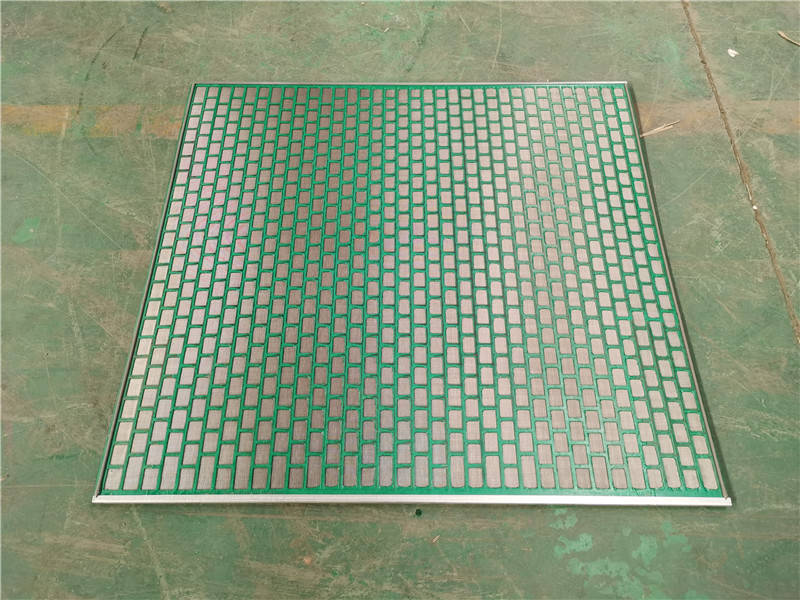

KET-M/M shaker screens have steel and PT frame types for your choice. Both of them are ideally as the replacement screens of SWACO MONGOOSE PRO and MEERKAT PT shale shakers. MONGOOSE units have 4 pre-tensioned screens per shaker basket and the MEERKAT units have 3 pre-tensioned screens per shaker basket. The mesh types are XR, XL, HC, MG available. AS a manufacturer, we provide adequate inventory and caring services unique for clients.

Adaptable Shale Shaker Model

KET-M/M shaker screens are used as the substitute screen for

SWACO MONGOOSE PRO shaker.

SWACO MEERKAT PT dual-motion shale shaker.

Competitive Advantage

Composite frame and PT frame optional.

SS 304/316 does not rust or delaminate.

Resistant to fluids that shorten steel frame screen life.

Manufactured according to the API RP 13C (ISO 13501).

Scientific & reasonable cost control system for competitive price.

Adequate inventory in the shortest time to meet customers' demand.

Warranty Period: 1 year.

Working Life: 400–450 hours.

Performance Parameter

| Screen Designation | Mesh Type | API RP 13C Designation | Conductance Number | D100 Separation (microns) | Non-Blank Area (sq.ft) | |||||||||||

| XR | XL | HC | MG | XR | XL | HC | MG | |||||||||

| KET-M/M-A325 | XR/XL | API 325 | 0.39 | 0.35 | - | - | 44 | 43 | - | - | 5.3 | |||||

| KET-M/M-A270 | XL | API 270 | - | 0.44 | - | - | - | 51 | - | - | 5.3 | |||||

| KET-M/M-A230 | XL/HC | API 230 | - | 0.55 | 0.79 | - | - | 58 | 62 | - | 5.3 | |||||

| KET-M/M-A200 | XR/XL/HC | API 200 | 0.81 | 0.91 | 1.1 | - | 72 | 74 | 74 | - | 5.3 | |||||

| KET-M/M-A170 | XR/XL | API 170 | 0.84 | 1.18 | - | - | 86 | 92 | - | - | 5.3 | |||||

| KET-M/M-A140 | XR/XL | API 140 | 0.99 | 1.48 | - | - | 110 | 103 | - | - | 5.3 | |||||

| KET-M/M-A120 | XR/XL/HC | API 120 | 1.4 | 1.64 | 1.61 | - | 119 | 126 | 120 | - | 5.3 | |||||

| KET-M/M-A100 | XR/XL/HC | API 100 | 1.65 | 2.17 | 1.96 | - | 147 | 141 | 142 | - | 5.3 | |||||

| KET-M/M-A80 | XR/XL | API 80 | 2 | 2.54 | - | - | 174 | 168 | - | - | 5.3 | |||||

| KET-M/M-A70 | XR/XL/HC | API 70 | 2.26 | 3.06 | 3.13 | - | 227 | 219 | 201 | - | 5.3 | |||||

| KET-M/M-A60 | XR/XL/HC | API 60 | 4.12 | 4.11 | 3.8 | - | 275 | 264 | 238 | - | 5.3 | |||||

| KET-M/M-A50 | XL | API 50 | - | 5.6 | - | - | - | 302 | - | - | 5.3 | |||||

| KET-M/M-A45 | MG | API 45 | - | - | - | 4.61 | - | - | - | 385 | 5.3 | |||||

| KET-M/M-A35 | XL | API 35 | - | 9.97 | - | 10.13 | - | 530 | - | 545 | 5.3 | |||||

| KET-M/M-A25 | XL | API 25 | - | 14.69 | - | - | - | 779 | - | - | 5.3 | |||||

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.* Conductance No.: This represents the ease with which a liquid can flow through the screen. Larger values represent higher volume handing. | ||||||||||||||||